Fast konkurrenskraftigt pris Topp precision CNC-svarv Service CNC-bearbetning Fräsning SUS Aluminium Mässing CNC-bearbetningsdelar Precisionslagerhus

Produktinformation

Ta på dig full skyldighet att uppfylla alla krav från våra kunder;få ständiga framsteg genom att främja våra kunders avancemang;växa till att bli den slutliga permanenta samarbetspartnern för kunder och maximera köparnas intressen för fast konkurrenskraftigt pris Topp precision CNC-svarvservice CNC-bearbetning Fräsning SUS Aluminium Mässing CNC-bearbetningsdelar Precisionslagerhus, din vägledning är vår eviga elektriska kraft!Varmt välkomna kunder i ditt eget hem och utomlands att gå till vår organisation.

Ta på dig full skyldighet att uppfylla alla krav från våra kunder;få ständiga framsteg genom att främja våra kunders avancemang;växa till att bli den slutliga permanenta samarbetspartnern för kunder och maximera köparnas intressen förKina maskindel och bildelar, Vi har kunder från mer än 20 länder och vårt rykte har uppmärksammats av våra uppskattade kunder.Oändliga förbättringar och strävan efter 0 % brist är våra två huvudsakliga kvalitetspolicyer.Har du behov av något, tveka inte att kontakta oss.

Projektanalys:

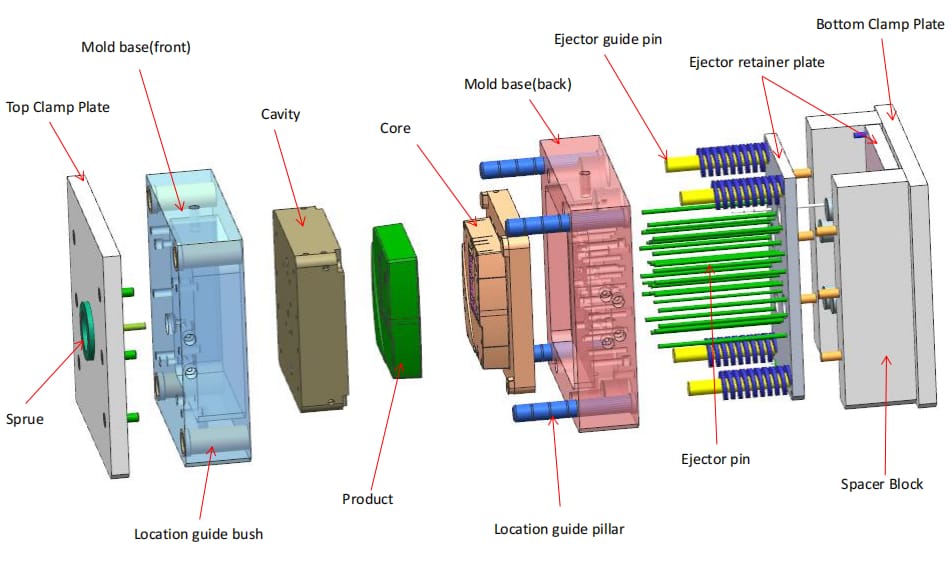

Efter att ha mottagit 3d-ritningar och krav från kunder kommer vårt ingenjörsteam att utvärdera dess strukturer och dimensioner för att diskutera och överväga hur formen ska utformas (såsom insprutningsgrinden, stift, dragvinkel etc.)

Produktionsprocess:

1. Fastspänning:

Verktyget stängs, vilket betyder starten på formsprutningscykeln.

2. Injektion:

Polymergranulerna torkas först och placeras i behållaren, sedan matas de in i fatet, där de samtidigt värms upp, blandas och flyttas mot formen med en skruv med variabel stigning.Skruvens och cylinderns geometri är optimerade för att hjälpa till att bygga upp trycket till rätt nivåer och smälta materialet.

3. Kylning:

Efter att verktygshåligheten är fylld måste hartset tillåtas svalna.Vatten cirkulerar genom verktyget för att hålla en jämn temperatur medan materialet härdar.

4. Utkastning

När materialet svalnar, stelnar det igen och tar formen av formen.Slutligen öppnas formen och den fasta delen trycks ut av ejektorstiften.Formen stängs sedan och processen upprepas.

5. Paket

De färdiga produkterna kommer att packas med plastpåse och läggas i kartonger.Särskilda förpackningskrav, kan också anpassas efter kundernas behov. Så att varje produkt kommer att levereras i gott skick. Anta full skyldighet att tillfredsställa alla krav från våra kunder;få ständiga framsteg genom att främja våra kunders avancemang;växa till att bli den slutliga permanenta samarbetspartnern för kunder och maximera köparnas intressen för fast konkurrenskraftigt pris Topp precision CNC-svarvservice CNC-bearbetning Fräsning SUS Aluminium Mässing CNC-bearbetningsdelar Precisionslagerhus, din vägledning är vår eviga elektriska kraft!Varmt välkomna kunder i ditt eget hem och utomlands att gå till vår organisation.

Fast konkurrenskraftigt prisKina maskindel och bildelar, Vi har kunder från mer än 20 länder och vårt rykte har uppmärksammats av våra uppskattade kunder.Oändliga förbättringar och strävan efter 0 % brist är våra två huvudsakliga kvalitetspolicyer.Har du behov av något, tveka inte att kontakta oss.